|

Dongying Mingde Petroleum Technology Co., Ltd

|

Sand Control Slotted Liner for Oilfield Well Water Well Gas Well Geothermal Well Well Completion

| Price: | 100.0 USD |

| Payment Terms: | T/T,L/C,D/P,WU,Paypal |

| Special Groups: |

Sand Control Screen Pipe (7)

|

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

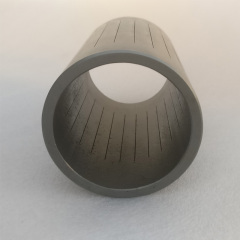

Sand Control Slotted Liner is mainly used for sand control of Oilfield Wells. Slotted liner is much more suitable for super heavy oil production.

Sand Control Slotted Liner and Screen Pipe for Oilfield

Sand Control Slotted Liner is mainly used for sand control of Oil Well, Water Well, Gas Well, Geothermal Well. It is good for well sorted reservoir, with features of low cost and easy run in hole operation.

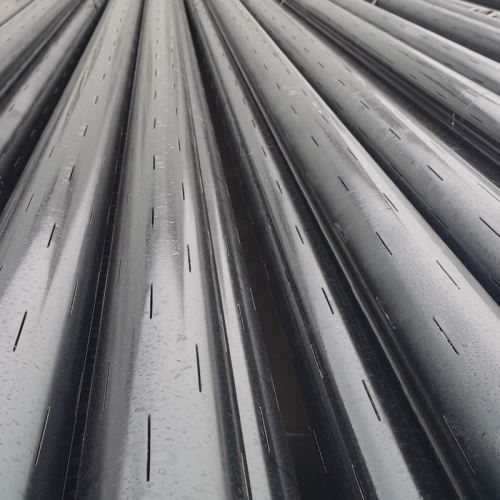

Main Parameters of Sand control slotted liner

| Base Pipe | API Spec 5CT Seamless Oil Tubing, Oil Casing Pipe |

| Steel Grade | API 5CT J55 K55 N80 L80-1, L80-9Cr, L80-13Cr, P110 |

| OD | 1.9''-7'' |

| Length | R1 R2 R3 |

| Slot width | 0.15-4mm |

| Slot length | 60-120mm ±1.0mm |

| Slots per circle | as per design |

| Distance between slots circle | as per design |

| Slot Type | Keystone slot and straight slot |

| Slot Surface | Low roughness with hard-quenched layer |

Application

Sand-control Completion of Open Hole Horizontal well, Side Well Drilling, Branch Well, and Gravel Pack Well Completion.

For further inquiry, you are welcome to contact Dongying Mingde Petroleum Technology Co., Ltd for further details.

Enhance well longevity, optimize production, and minimize maintenance with our Sand Control Slotted Liners—a premium solution engineered for efficient filtration and structural integrity in demanding well environments. Designed for oilfield wells, water wells, gas wells, and geothermal wells, our slotted liners are the go-to choice for reliable well completion across industries.

Key Features & Benefits

Precision Sand Control

Advanced slotting technology prevents sand and particulate ingress while maintaining optimal fluid flow.

Ideal for unconsolidated formations prone to sand production, reducing downtime and equipment wear.

Versatile Application

Compatible with oil and gas wells, water wells, and high-temperature geothermal wells.

Customizable slot sizes, patterns, and materials (stainless steel, carbon steel) to match reservoir conditions.

Enhanced Well Productivity

Maintains reservoir integrity by balancing inflow control and sand retention.

Reduces screen plugging risks, ensuring consistent production rates.

Durable Construction

Corrosion-resistant materials withstand harsh downhole environments, including high-pressure and high-temperature (HPHT) conditions.

Robust design ensures long-term performance in geothermal and offshore applications.

Cost-Effective Well Completion

Eliminates the need for gravel packing in many scenarios, lowering installation time and operational costs.

Easy integration with existing well casings and completion systems.

Materials: Premium-grade stainless steel, carbon steel, or alloy options.

Slot Sizes: 0.012" to 0.25" (customizable based on formation analysis).

Diameter Range: 2" to 12" (tailored to wellbore dimensions).

Temperature Resistance: Up to 600°F (315°C) for geothermal applications.

Oilfield Wells: Prevent sand intrusion in horizontal, vertical, and deviated wells.

Water Wells: Ensure clean water extraction with minimal sediment contamination.

Gas Wells: Stabilize production in shale and unconventional reservoirs.

Geothermal Wells: Withstand extreme temperatures while maintaining structural integrity.

Custom Engineering: Slot patterns optimized for your reservoir's particle size distribution.

Global Compliance: Meets API, ISO, and NACE standards for quality and safety.

Expert Support: End-to-end assistance from design to installation.

Technical Specifications

Applications

Why Choose Our Slotted Liners?

Boost Efficiency, Cut Costs, and Extend Well Life

Invest in slotted liners that deliver unmatched sand control and flow efficiency for oil, gas, water, and geothermal well completion.

Keywords: Sand Control Slotted Liner, Oilfield Well Completion, Water Well Sand Control, Gas Well Liners, Geothermal Well Solutions, Slotted Liners for Well Completion, Sand Management in Oil and Gas, Durable Well Screens, Custom Slotted Liners, HPHT Well Equipment.

Optimize your well performance today—contact us for a tailored solution!